FLOAT GLASS

We are specialized in high quality tempered float glass and low iron patterned glass:

If you demand float glass we can supply customized sizes, different colors, silk printed in different thicknesses. During the recent years we have developed projects within tempered float glass for several different kind of industries like kitchen, furniture, wardrobes, bathroom, bus shelters, railings, interior, shelf, decorations, public advertisements and more.

Tempered glass is formed by heating glass to the softening point in a horizontal tempering furnace and then quickly cooling it with cold air. This technique resists compressive stress on the surface and tensile stress inside which provides bending/shock resistance. If breakage it splits into very small harmless particles.

We supply in customized sizes – in thicknesses from 3 to 19 mm – industrial packed in crates. Alternative – customized packing in combination with other kind of hardware.

MIRROR

We are specialized in high quality mirror production and processing of all kind:

We supply copper-free silver, aluminum mirror and high class mirrors according to customers individual drawings and demands. During the recent years we have developed projects within different kind of mirror business like kitchen, furniture, wardrobes, bathroom, interior, decorations.

We supply also mirror with safety foil and our customer can cut to measure by themselves, or in customized sizes – industrial packed in crates.

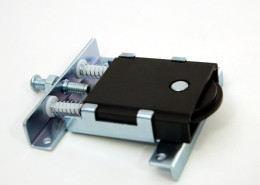

Alternative – customized packing in combination with other kind of hardware like hinges.

LAMINATED GLASS

We are specialized in laminated glass of all kind. If you demand laminated glass we can supply customized sizes, colors and thicknesses like:

· clear laminated glass

· tinted glass laminated glass

· reflective glass or low-e glass laminated glass

· mirror laminated glass

· patterned glass laminated glass

· tempered laminated glass

Safety laminated glass are made up of two or more sheets of glass bonded together with a PVB (polyvinyl butyral) interlayer in a heat and pressure process. In the event of breakage the glass fragments remain bonded. Laminated glass never splinters, has good sound insulation, insulate most UV and can be bullet proof.

We look forward to receive your enquiry

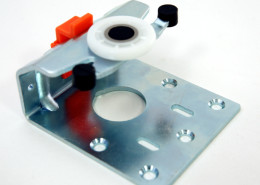

We offer our customers pre-assembling and packing in our warehouse facilities in Shunde China.

We offer our customers pre-assembling and packing in our warehouse facilities in Shunde China.

We are happy to offer our customers service, support, advice and guidance during the design and development process.

We are happy to offer our customers service, support, advice and guidance during the design and development process.