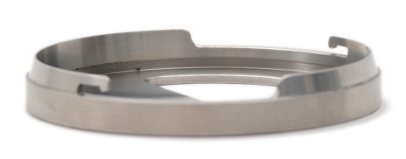

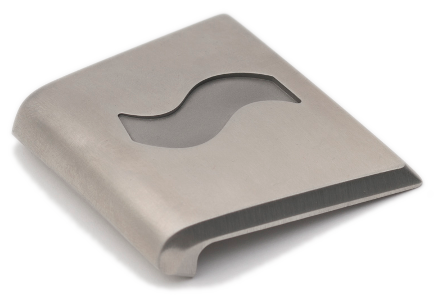

Stainless steel

Precision investment casting

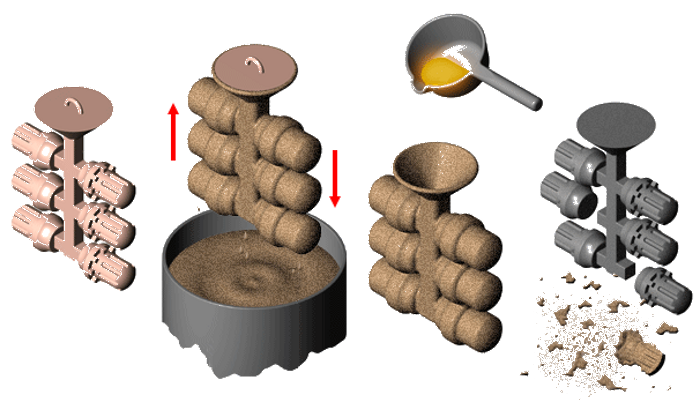

Precision investment casting in stainless steel, also known as lost wax casting, is a flexible production method where any shape can be produced. Investment casting is also a attractive method for small production runs. We offer all common alloys, if you have special alloy requirements we will most likely be able to help you also.

We offer a large range of post-processing services for machining, surface finish and print, please see data sheet below.

We have offices and staff in China, ISO9001 certified, running a complete quality management system, insuring that components will seamlessly drop into your production flow. Also we have our own test laboratory located in China.

Need assembly or ready for retail packing? No problem – with our own warehouse facilities and staff in China, we can assemble and pack.