Investment casting in stainless steel, titanium and aluminium

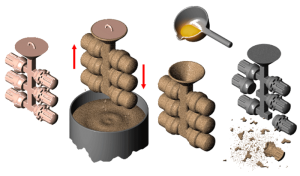

Investment casting is a more than 5000 year old technology, today developed to perfection, so much so that its also called precesion casting. Another name is lost-wax casting, and as the name implied an item is cast i wax, the wax item is then coated in a cheramic compound. This ceramic mold is then filled with molten metal, that burns out the wax and replaces it with metal.

Compfitt Group has years of experience with precision casting in stainless steel, titanium and aluminium.

The cast components can be post-processed with CNC milling and other methods. The surface can be polished, brushed or painted to achieve the look and function desired, like the polished surfaces required in the food industry.

Investment casting is a flexible technology, that does not require large production runs, and the technology works well with complicated shapes. Often a component design can be optimized to achieve advantages in following mounting processes or reduce the number of components required. Item size range from 5 grams to 150 kg.

Compfitt Group has its own division in China, not far from Hong Kong, taking care of quality control and logistics. With warehouse facilities in Denmark, Germany and China, we can offer warehousing and just-in-time delivery.

We also offer component assembly and packaging. Manufacturing takes place at our long term partners, at various locations in China.

Compfitt Group is ISO9001 certified in Denmark and China, latest in 2016.

Leave a Reply

Want to join the discussion?Feel free to contribute!